State of Clean Cooking in Africa

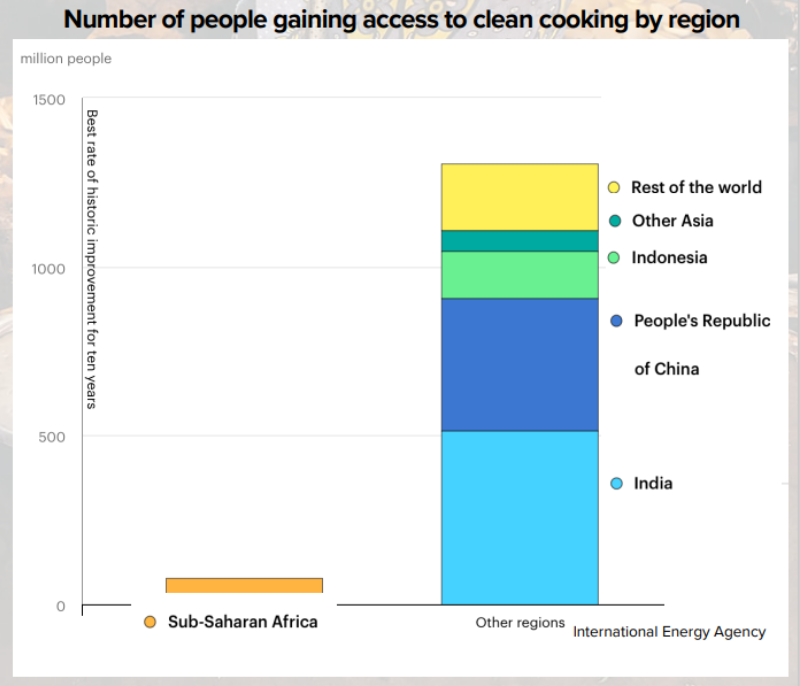

Globally, since 2010, the number of people without access to clean cooking technology has gone down. This decline is attributed to subsidized clean energy projects within Latin America and Asia. However, despite this global decline, the total number of people in Sub-Saharan Africa without access to clean cooking technology has been rising. The available energy in the country cannot keep up with the population and economic growth. Today, 1 billion people in Africa (roughly 4 out of 5 people) continue to rely on highly dangerous and polluting traditional open fire stoves. stove to be much more fuel efficient while simultaneously reducing harmful emissions. In doing this, BDL designed stoves decrease fuel collection time, improve cooking conditions, as well as being culturally appropriate and sustainable within communities. By investing in clean cooking solutions, we combat the growing energy disparities, reduce harmful emissions, improve public health, and empower women through education and economic opportunities. Clean cooking technology is not just an environmental imperative but a vital tool for social and economic transformation.

The statistics continue to be alarming. According to the International Energy Agency every year 3.7 million premature deaths are attributed to a lack of clean cooking technology. Smoke inhalation and indoor air pollution from these traditional cooking methods causes respiratory complications and cardiovascular disease. In Africa, women and children account for nearly 60% of these deaths.

The health issues caused by these emissions as well as the time consuming nature of fuel collection often prevent and disrupt educational opportunities for women. Without education women become subject to a vicious cycle of gender inequality that perpetuates harmful classical gender roles and diminishes female autonomy.

There are multiple clean energy cooking solutions such as stoves fueled by natural gas and electricity, however for many communities those solutions are often not affordable, accessible, or adoptable. Burn Design Lab is working to create stoves that fulfill all of those needs. Our stoves continue to use bio fuel such as wood or coal, but we design the stove to be much more fuel efficient while simultaneously reducing harmful emissions. In doing this, BDL designed stoves decrease fuel collection time, improve cooking conditions, as well as being culturally appropriate and sustainable within communities.

By investing in clean cooking solutions, we combat the growing energy disparities, reduce harmful emissions, improve public health, and empower women through education and economic opportunities. Clean cooking technology is not just an environmental imperative but a vital tool for social and economic transformation.

Cookpot Casting & Technology Transfer

In June, the institutional stove team collaborated with Gil’s Aluminum Foundry in Seattle’s Georgetown to create a pattern for a molding system to produce a new cookpot casting for the stove. In order to create the pattern at a relatively low cost, our engineers created a cookpot pattern with our inhouse 3D printer. This process involved 56 hours of printer time to produce 33 individual pieces needed to build the pot. These were then carefully glued together to form the rough pattern. After review by Gil’s Foundry owner Andrew Lee, the team began the process of smoothing the pattern by applying filler and sanding.

This process was repeated several times with the pattern becoming progressively smoother with each iteration. As a last step, the pattern was painted with primer and delivered to the foundry. At Gil’s Aluminum Foundry the pattern was then placed into a rectangular flask where it was surrounded and packed with sand to create the mold cavity. The cavity was then cast with aluminum to create the cookpot.

In Sierra Leone, with Westwind Energy, the stove will be built for use in schools and hospitals. However the current casting method varies significantly from that in the U.S., being far more hazardous, variable, and exhausting. At Burn Design Lab, our approach extends beyond creating safe cooking equipment; we are also committed to the implementation of safe domestic stove manufacturing practices. We seek to enhance the existing in-country manufacturing systems through a process known as technology transfer. At the United Nations Conference on Trade and Development technology transfer was described as “...essential for economic development…”. With the UN Industrial Development organization outlining how “the most dynamic sector for making advancements in this sense is the manufacturing sector”. By providing Sierra Leone with advanced manufacturing technologies, methods, and practices, we aim to improve safety, efficiency, and productivity within the manufacturing sector. This not only ensures a safer working environment but also boosts economic growth. Improved manufacturing processes lead to better product quality, reduced waste, and increased production rates, which contribute to the overall development of the country.

The intensive design process and collaboration with Gil’s Aluminum Foundry in Seattle, has furthered our commitment to clean cooking technology. As we move forward, the global improvement of manufacturing processes will foster safer working conditions and economic prosperity.

Board of Directors Spotlight: Sarah Agbey

Sarah Naa Dedei Agbey is a seasoned development practitioner with over 25 years of experience in Planning, Organizational Development, and Good Governance. She holds an M.Sc. in Regional Planning and Management and has extensive training in Renewable Energy, Climate Change, and Environmental Impact Assessment.

At Burn Design Lab, Sarah’s strategic insights and hands-on experience in West Africa environmental governance and sustainable development are invaluable to the board.

Joining SNV-Ghana in 2005 and rising to Deputy Country Director in 2017, Sarah has played a crucial role in strategic planning and capacity building for numerous organizations. She has been instrumental in initiatives related to climate change, renewable energy, and good governance.

Currently leading Growth Solutions, Sarah is actively involved in developing a National Clean Cooking Strategy for Ghana. She also serves on the boards of multiple organizations, reinforcing her belief in building strong systems and sustainable markets. Sarah’s dedication to sustainable development and her expertise make her a pivotal member of Burn Design Lab’s board, driving impactful change and innovation.