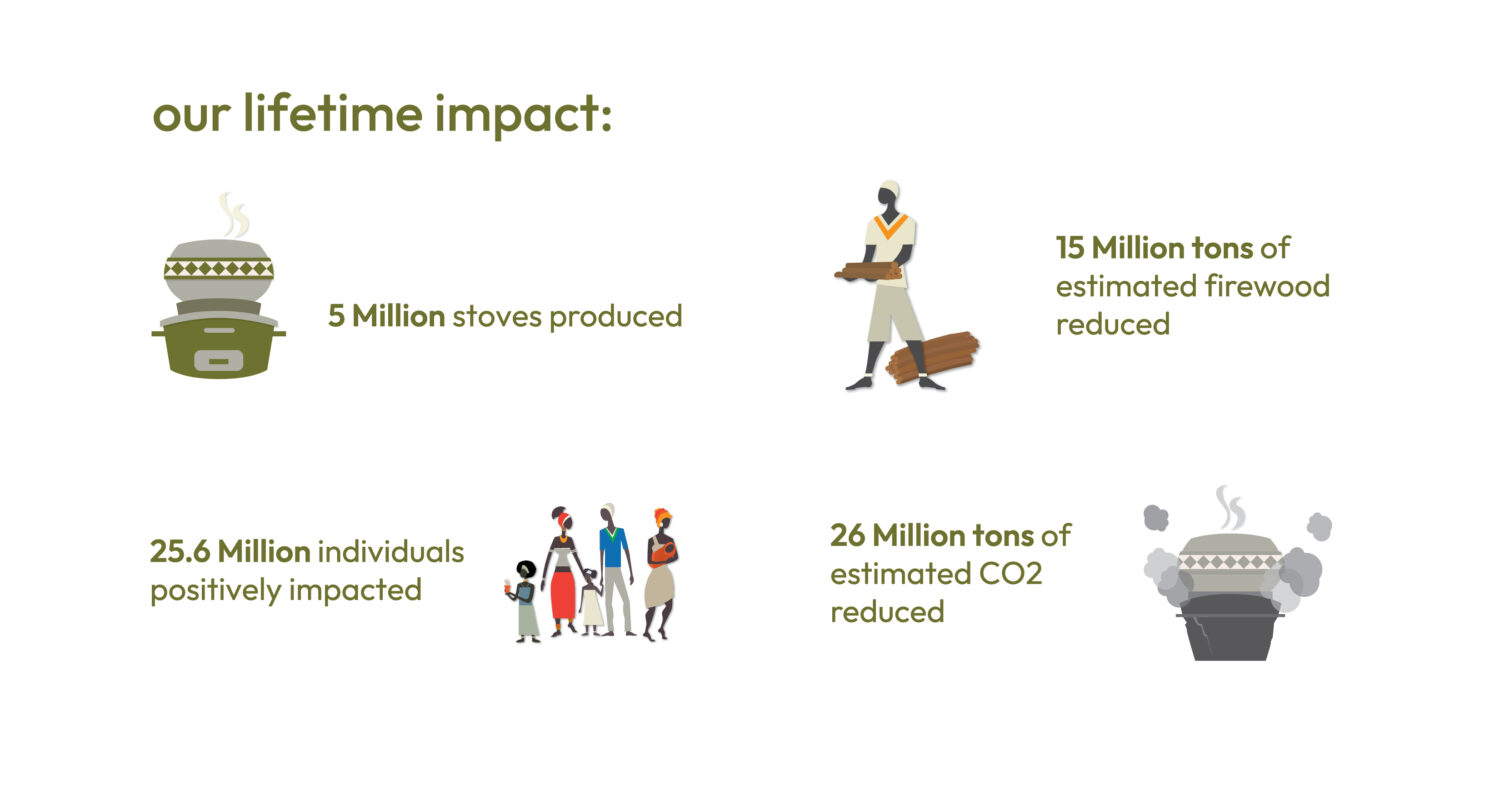

Our Impact

At Burn Design Lab, we want women in the developing world to live better, healthier lives through improved access to cleaner-burning cookstoves. The positive impact of our cookstove projects has reached women, families, homes, schools, and places of work across the world.

Our Impact in East Africa

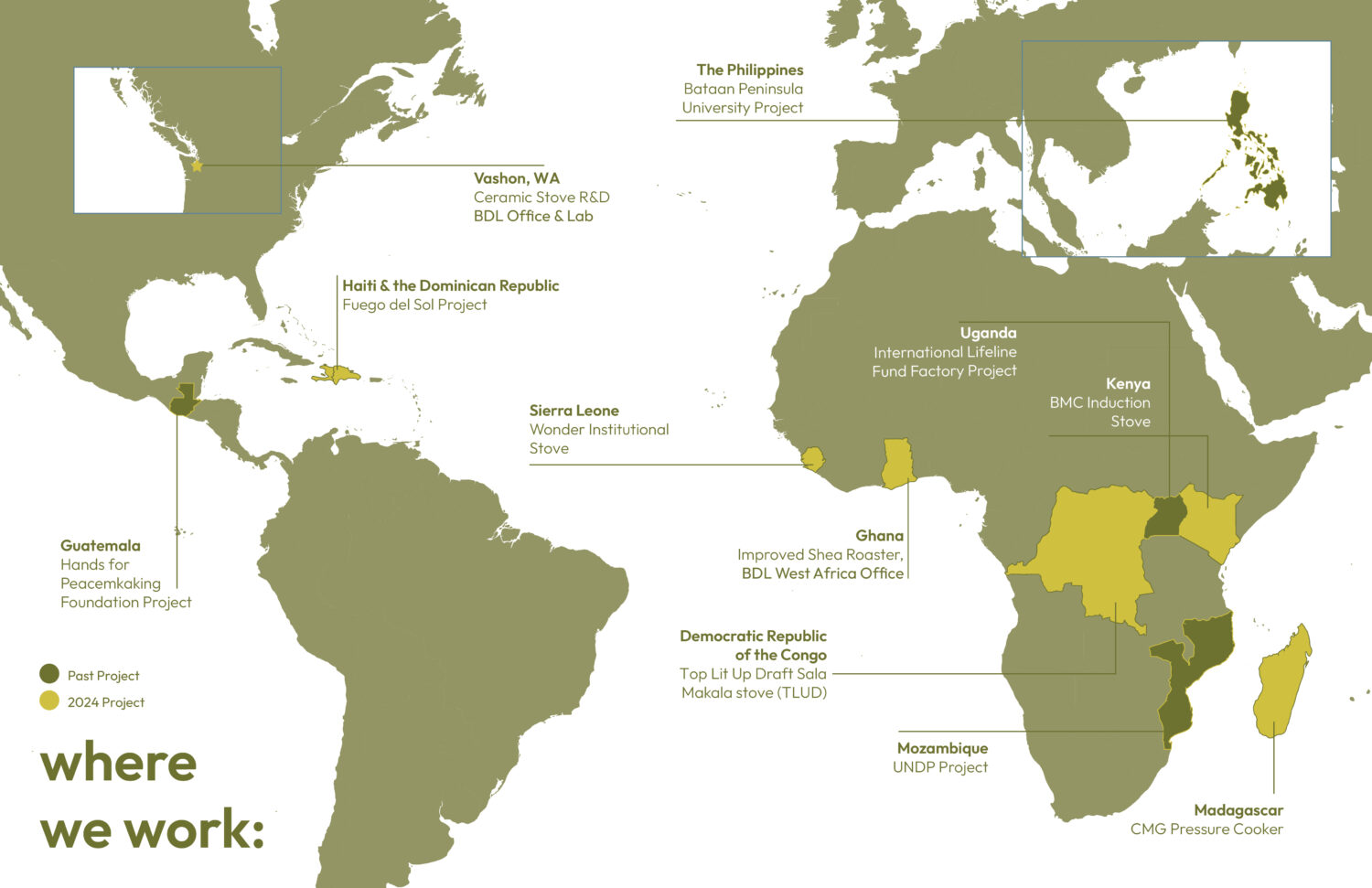

BDL's earliest projects include the Jikokoa and Kuniokoa stoves, for use in Kenya. After the stoves' initial design, Burn Design Lab founder Peter Scott then created Burn Manufacturing and relocated to Nairobi, where the two stove designs are manufactured and sold. Learn more about Burn Design Lab's history.

Since their initial design, the Jikokoa and the Kuniokoa, now called the ECOA Char and the ECOA Wood, have had an enormously positive impact on families in Kenya and other parts of East Africa. More than 1,400,000 ECOA Char stoves have been sold since 2014 and it is considered the world's most fuel-efficient charcoal stove. Together with the ECOA Wood and other stoves sold by Burn Manufacturing, the BDL-designed ECOA Char has positively impacted more than 27 million people, saved an estimated 29 million tons of firewood, and reduced CO2 emissions by more than 50 million tons.

Our Impact in West Africa

In 2018, Burn Design Lab began work on an improved Shea Roaster in order to positively impact the health and livelihoods of women processing Shea across Ghana and other parts of West Africa. Since 2018, more than 40 BDL Improved Shea Roasters have been manufactured locally and deployed in Shea Cooperatives. These roasters have directly impacted more than 1,600 women across Ghana. In 2025, BDL announced a partnership with the Haydon Kirkwood Charitable Trust to manufacture an additional 15 roasters, to be deployed across 7 different cooperatives. Thanks to the support of the HKCT, the impact of BDL roasters will reach an additional 1,000 women.

Rafia Mohammad speaks on the impact the BDL Improved Shea Roaster has had on her job processing shea nuts into butter.

In Sierra Leone, BDL has partnered with Westwind Energy and together we've worked on the new generation of the Wonder Institutional Stove, for use in large scale cooking, specifically in schools. In 2024, BDL helped design and implement an interim production system to bring WWE’s manufacturing capacity to over 50 stoves per month.

BDL is continuing their strong partnership with Westwind Energy (WWE) in Sierra Leone to enhance the existing design of the Haja Posseh (HP) Wonder Stoves, including both wood and charcoal fuel designs. Together, BDL and WWE aspire to impact millions of households with access to cleaner burning cookstoves over the next decade.