2022-2023 Shea Roasting Season in Review

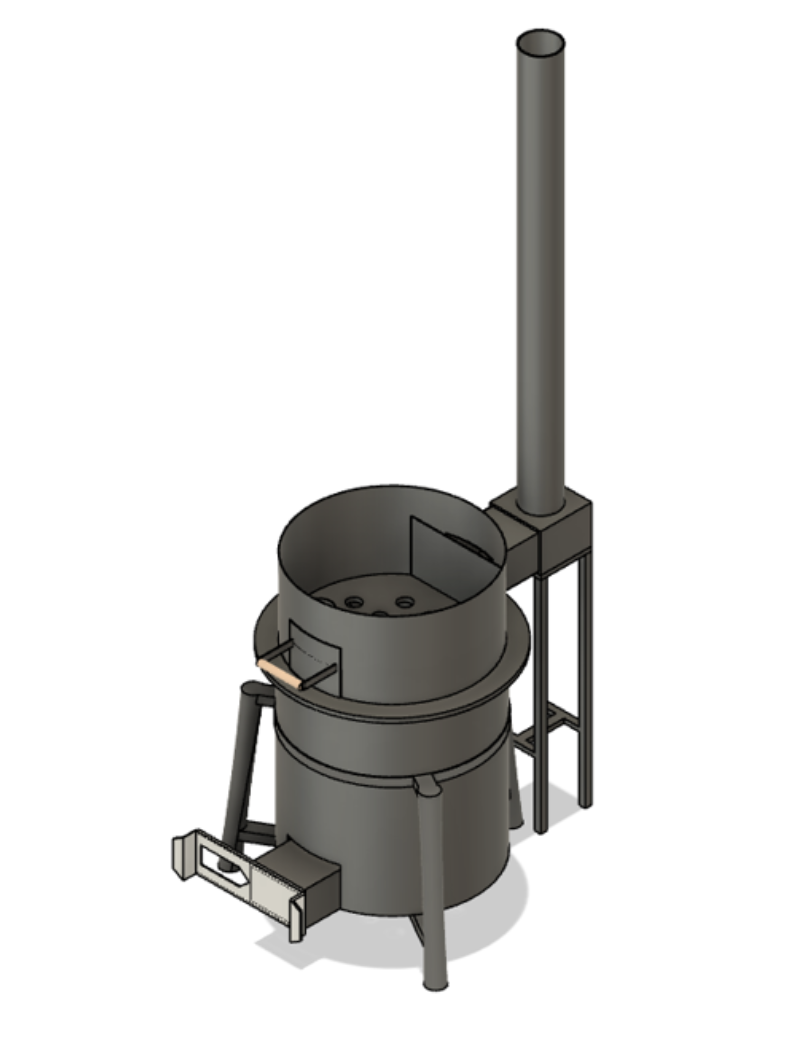

In 2023, our team partnered with a new Ghanaian manufacturer, SAYeTECH, to produce 26 units of our improved shea roaster design. These roasters were installed at 10 different cooperative locations across northern Ghana, providing over 1500 women with improved roasting technology Our local team trained over 1500 women on the use, operation, and maintenance of the improved roaster and has followed up to collect feedback and durability data.

The team has also been monitoring and evaluating the roasters from our Pilot Phase in 2022. Over the 2022-2023 season, these nine Pilot roasters have been used on:

417 DIFFERENT OCCASIONS, FOR A TOTAL OF

119,111 MINUTES, ROASTING AN EQUIVALENT OF

135,786 KG OF SHEA NUTS.

Based on this data, BDL estimates a reduction of:

14 TONS OF WOOD FUEL,

26 TONS OF CO2, AND

1060 WOMEN OPERATING HOURS.

BDL has an extensive training program with the women at the shea butter cooperatives, which we follow with regular check ins to make sure that the roasters are being used properly. Our wider scale rollout to some new cooperatives in 2023 saw an increased use of wet fuel resulting in increased smoke exposure. To combat this, our team held follow up trainings at these select cooperatives to reinforce the proper fuel usage in our roasters.

These roasters have been installed mainly with our primary implementing partner, the Savannah Fruits Company, and funded through their sustainability program. We have been working with our partner, SAYeTECH, and an external consultant, Studio Carbon (awarded to us through the ASME Innovation Showcase Award which we received in June 2023) to improve our marketing strategy. At the same time, we are trying to lower the cost of materials and manufacturing so that we can make this more accessible to women in the shea value chain.

The shea roaster project is currently being implemented (shea roaster manufactured and used) in northern Ghana. Through expanding the availability of improved roasters, we are increasing the impact and efficiencies of the production of hand-crafted shea butter.

BDL Begins Project in Haiti

In Haiti, households rely almost exclusively on wood and charcoal to meet their cooking energy needs. Harvesting wood for household cooking in Haiti contributes to more than 300,000 tons of woody biomass loss every year. Yet, making charcoal is also an important form of employment for Haitians – it is the country’s second-largest agricultural value chain. Combined, these two competing realities make for a complex energy landscape. El Fuego del Sol (FdS), a social-eco enterprise based in Port-au-Prince, Haiti. They are a full-service waste management, recycling, clean cooking, and reforestation enterprise working to improve environmental, economic and health conditions in Haiti and the Dominican Republic. FdS approached Burn Design Lab to provide third party testing to assess the performance and potential impact of their Fuego del Sol Generation 9 Stoves.

El Fuego del Sol was founded in 2005. While the organization originally planned to work on water purification, conversations with locals about the daily needs in their lives revealed that cooking was a serious problem. With a joint Haitian-Dominican-American founding team, El Fuego del Sol was born. BDL BEGINS PROJECT IN HAITI FdS stoves are built by local fabricators in Haiti, and are sold and distributed to local organizations and institutions. They provide full training for cooks on the proper use of the stove, as well as full installations on-site to ensure that the stoves have proper ventilation.

BDL is glad for the opportunity to use our team’s expertise in improving cookstoves to help the clean cooking landscape in the Dominican Republic and Haiti. The county’s recent history has been challenging and the cost of clean electricity is too high to make cooking on electricity an affordable option for most households in the DR and Haiti right now. That’s where BDL’s experience will help FdS and the people of the DR and Haiti. With your help, we are reaching the underserved billions across the globe unable to access truly “clean” cooking.

.ORG Impact Award Finalist: Improved Shea Roaster

Burn Design Lab was selected as one of just 35 finalists for the .ORG Impact Awards by the Public Interest Registry (PIR) for our work on the improved shea roaster project in Ghana. Nearly 1,000 nonprofit organizations from more than 70 countries applied. The .ORG Impact Awards are a prestigious global awards program that recognizes and rewards outstanding mission-driven individuals and organizations from around the world for their positive contributions to society. As a finalist for the .ORG Impact Award in the Environmental Stewardship category, the opportunity to share our work with a global audience is immensely valuable to us. Our improved shea roaster project positively impacts women in the shea butter industry, improving their working conditions while preserving the local environment.

We are so grateful to every one of you who have helped us along the way. The improved shea roaster project has been a labor of love for our team and there were times we did not know how we would fund the next stage of work. You, our donors, have stepped up time and again to see this project to the current place of success where we are now having a tangible, daily impact on the lives of women whose livelihood is producing shea butter. Thank you